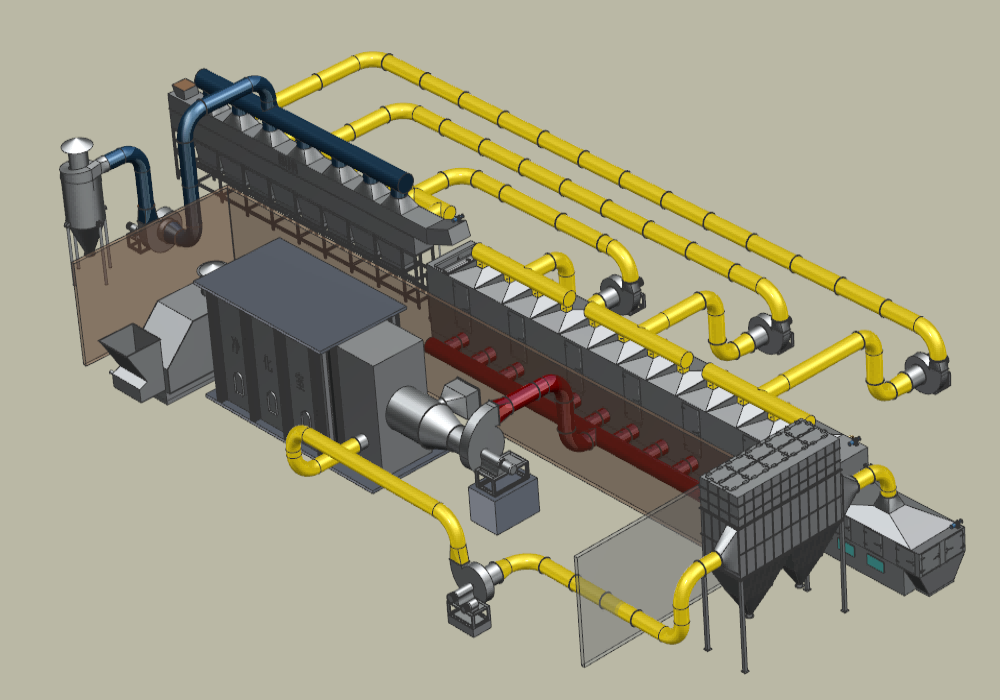

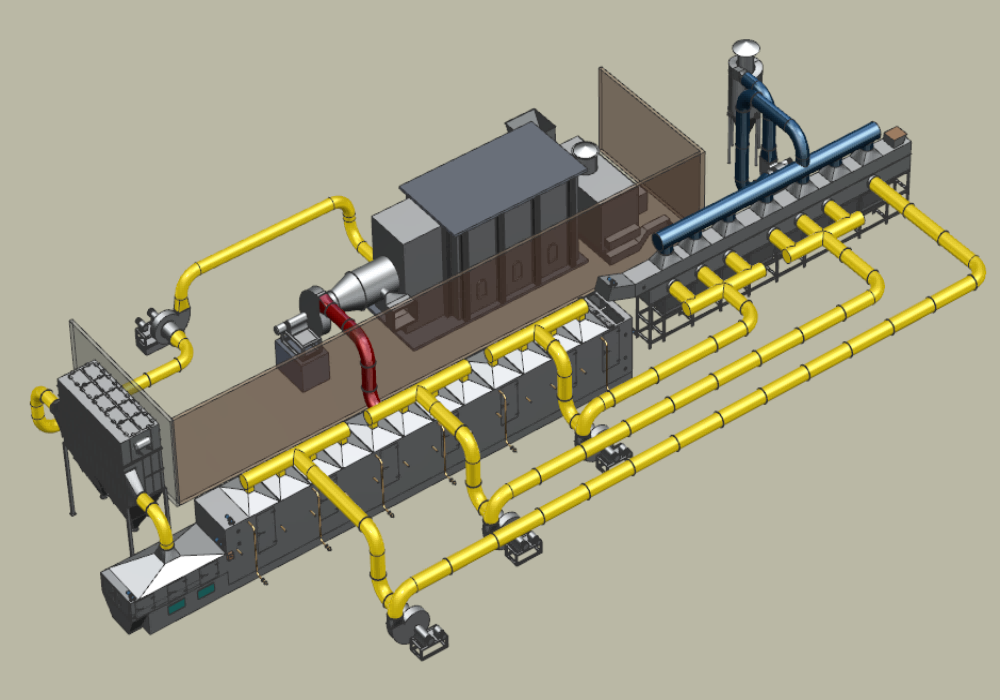

Belt Dryer

The DW series multi -layer band -type dryer is a continuous drying equipment for production for production. It is used for drying the dried, strip -shaped, and granular materials with better ventilation. High, and materials with high material temperature are particularly suitable; this series of dryers have the advantages of fast drying speed, high evaporation strength, and good product quality. It can be dry after the shape.

The DW series multi -layer band -type dryer is suitable for difficult drying materials with low drying rates in large -scale production. The equipment structure is compact, the area is small, the operation is simple, the maintenance is convenient, and the operation is stable. It can be designed in different hot air circulation and dry forms according to the drying characteristics of the material. It is an extension and improvement of the hot air circulating oven. It is widely used in metallurgical aids, chemicals, food, packaging and other fields. With the advancement of enterprises and the improvement of product technology content, the multi -layer strip dryer has the ability to meet large production, diversification, centralized control, and continuous production. It has the advantages of efficient, energy conservation and easy management.

Because it is necessary to install and unload it in the operation, it is not suitable for drying and easy to stick to the conveyor belt and non -allowed materials.

The characteristics

Multi -layer band -type dryers are widely used in the type, strip -shaped, block and granular materials of food, agricultural and sideline products, dehydrated vegetables, Chinese herbal medicines, aquatic products, souvenirs, feed and chemical raw materials Essence This series of dryers has the characteristics of efficient and energy -saving. It has domestic leading level in the aspects of heating, heating, layering into the wind, turning and drying segments, and removing heat recovery.

1. This series of drying machine stalls are placed in the processing materials of the processing materials of multi -layer mobile stainless steel mesh or vibration boards. The quality of the product is good, with a cooling layer and rotating input device, which is low in the material temperature and is conducive to timely packaging.

2. Use a lift device with a uniform material, the thickness is uniform, and the thickness of the ingredients can be regulated without stepping.

3. The area of ??the stalls from 25m2 ~ 80m2, seven models of different sizes can meet the needs of a variety of materials and different production scale.

4. In the long -term production practice process, the device structure is adjusted according to the actual experience of customer production and use, and the series of products are continuously optimized and updated to develop a variety of structured forms. It has targeted design and good products of different nature products. Effect. The series of products are now improved according to the equipment structure as the following specifications.

5, the bottom of the wind, penetrate multi -layer penetration, the tail gas is directly discharged.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)