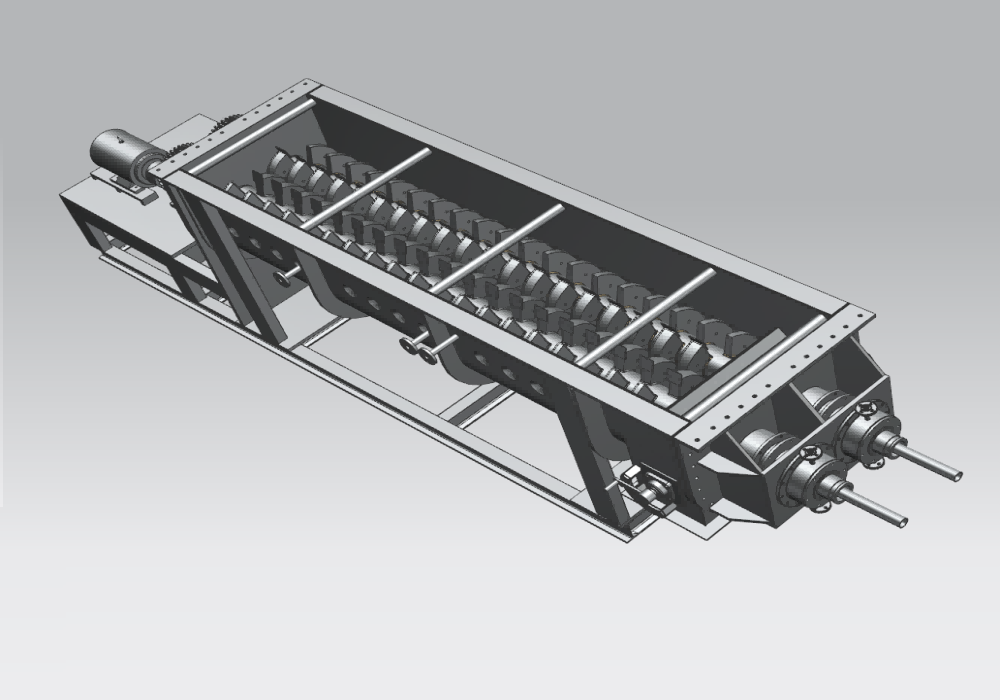

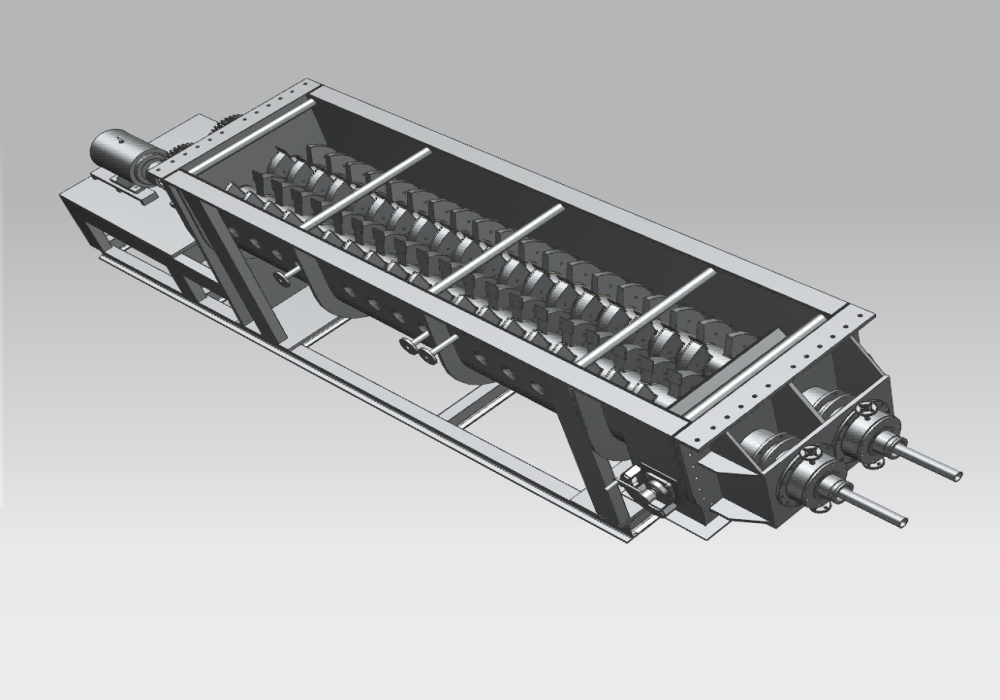

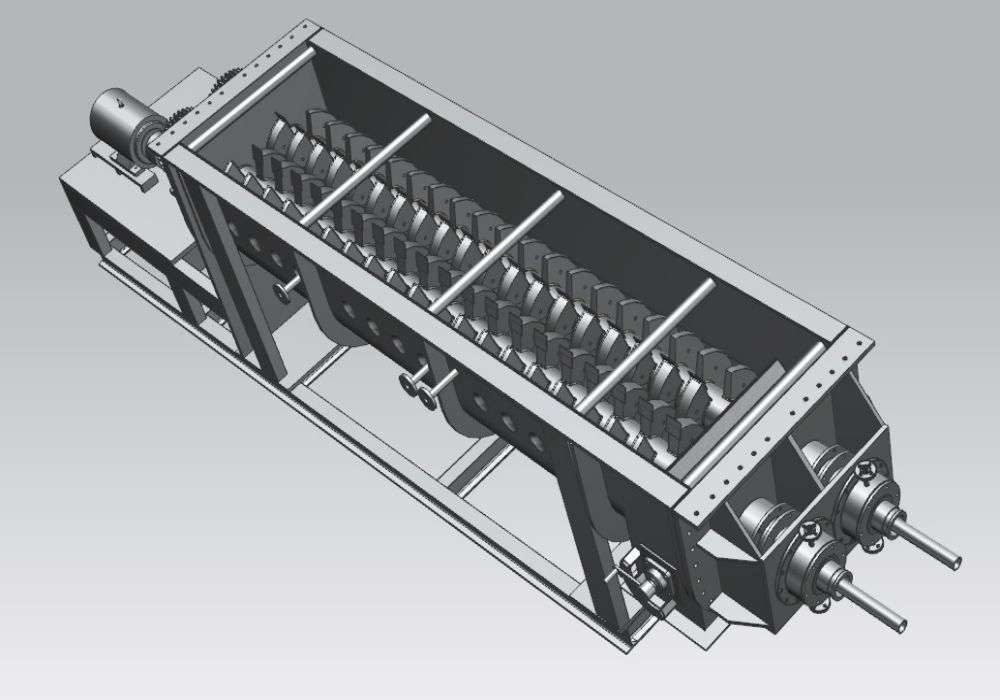

Hollow Paddle Dryer

The empty paddle -leaf dryer is a continuous drying equipment based on thermal conductivity. Because the mixing blades are like paddles, they are called paddle dryers, and foreign countries are also called groove dryers or mixing dryers. Because the heat required for drying depends on the heat guide indirect heating, the drying process does not require or only requires a small amount of gas to take away the wet portion. It greatly reduces the heat loss taken away by the airflow and improves the heat utilization rate. It is a energy -saving drying equipment. Port -leaf dryers are widely used in the drying of powder, granular, filter, and slurry -like materials in industries such as petrochemical, chemical, metallurgy, metallurgy, food, medicine, medicine, pesticide, etc.

The working principle of hollow paddle dryer dryer

There are several parts such as leaves, stirring shafts, and wall surfaces such as hollow paddle -leaf drying machines, and the heat transfer area of ??the leaves accounts for a large part, so the equipment structure is compact and the unit volume transmission area is large. In addition, stirring and mixing can cause the material to flip violently, so as to obtain a high heat transfer coefficient, so the area and space are small, saving the cost of infrastructure in the plant. The amount of gas in the drying process is small, the flow velocity is low, and the amount of dust taken away by the gas is small. Therefore, the gas dust recovery after drying is convenient to recycling, the volume of the recycling equipment is small, which can save provincial equipment investment.

Due to the special structure of the paddle, the material was squeezed and relaxed during the drying process, which strengthened dryness. The full rate of drying indoor materials is very high, which can reach 80%to 90%. The stay time of the materials can be adjusted by adjusting the speed of the material, the speed of the mixing shaft, and the full material of the material, and it is adjusted from several minutes to a few hours. In addition, the material in the dryer mouth is basically piston movement from the ingredient mouth, and the residence time is narrow, so the product's water content is uniform. The paddle leaves have a certain axial angle on the stirring shaft, so they can be dried continuously.

The performance characteristics of hollow paddle leaves dryer

1. Low energy consumption, small operating costs: the equipment structure is compact, the effective heat transfer area is large, and the area is small;

2. The range of applicable materials is wide: the use of different thermal medias can handle the thermal sensitivity materials and the materials that need to be high -temperature and dry. Common media are: water steam, heat conductive oil, hot water, cooling water, etc. It can be continuously dry or intermittently dry, and can be applied in many fields.

3. Stir well, high thermal efficiency, good drying effect;

4. The axis of the paddle can be meshing with each other, which has a self -cleaning effect to prevent the material sticky wall;

5. The dust clips are small, the material loss is small, and the environmental pollution is small; for the contaminated materials or the working conditions that need to be recycled, a closed circulation or vacuum drying can be used.

Scope of application range

The paddle -leaf dryer has been successfully used in food, chemical, petrochemical, dye, industrial sludge and other fields. The characteristics of equipment heat transfer, cooling, and stirring can make the following unit operations: burn (low temperature), cooling, drying (solvent recovery), heating (melting), reaction and sterilization.

1. Use thermal conductivity to make the heat medium, and the dryer dried machine can complete the low -temperature burning work. Such as: calcium sulfate (CA2SO4 · 2H2O) is converted into semi -water sulfate (CA2SO4 · 1/22H2O). Sodium bicarbonate (NAHCO3) was converted into soda -alkali (NA2HCO3) and so on.

2. Cold medium, such as water, cooling saline, etc. can be used to cool. Such as: the slurry -type cool alkali machine used in the pure alkali industry, replaced the old -fashioned air cooling cold alkali machine, saved energy and tail gas treatment equipment, reduced operation costs, and can also be used for titanium pink, nickel powder alloy powder and various types Cooling of powder -like materials. In a single machine, the material can be cooled from 1000 ° C to less than 40 ° C.

3. The main functions of drying equipment are not using hot air, so that solvent recovery, energy consumption, and environmental control are in an ideal state of easy processing. It is particularly adapted to the need to recycle solvents, flammable and oxide thermal materials. It has been widely used for fine chemicals, petrochemicals, and dyes.

4. In the axial interval, the uniformity of temperature, humidity, and hybridness makes the device use to heat or melt, or perform some solid material reactions. Both compound fertilizer and transgender starch industries have been successfully used. The slurry dryer can be used to sterilize food and flour. The large heating area of ??the unit's effective volume will soon heat the material to the sterilization temperature, avoiding long -term heating and changing the quality of the material.

| model item |

KJG-7 | KJG-15 | KJG-29 | KJG-41 | KJG-52 | KJG-68 | KJG-81 | KJG-95 | KJG-110 | KJG-150 |

| heat transfer area(m²) | 7 | 150 | 29 | 41 | 52 | 68 | 81 | 95 | 110 | 150 |

| Effective volume(m³) | 0.25 | 0.6 | 1.85 | 2.8 | 3.96 | 5.12 | 6.43 | 9.46 | 11.67 | 16.4 |

| Blade outer diameter(mm) | 300 | 500 | 700 | 700 | 900 | 900 | 1000 | 1100 | 1200 | 1400 |

| Lower box length(mm) | 3400 | 3550 | 3900 | 5500 | 5500 | 6400 | 6500 | 6900 | 7000 | 7400 |

| total length(mm) | 5000 | 6000 | 7000 | 8600 | 9200 | 9800 | 10000 | 10800 | 11500 | 13500 |

| Lower box width(mm) | 580 | 940 | 1300 | 1300 | 1700 | 1700 | 1900 | 2100 | 2300 | 2600 |

total width(mm) |

1100 | 1200 | 1900 | 1900 | 2400 | 2400 | 2800 | 3000 | 3200 | 3600 |

| total height(mm | 1500 | 1800 | 2100 | 2100 | 2600 | 2600 | 2800 | 3100 | 3300 | 3800 |

| Transmission power(kw) | 3 | 7.5 | 18.5 | 30 | 37 | 45 | 55 | 75 | 90 | 132 |

| Equipment gross weight(T) | 2.5 | 5.5 | 12 | 16 | 20 | 32 | 41 | 52 | 78 | |

| Note: All models below 150m² are double-axis, and all models above 150m² are four-axis. | ||||||||||

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)