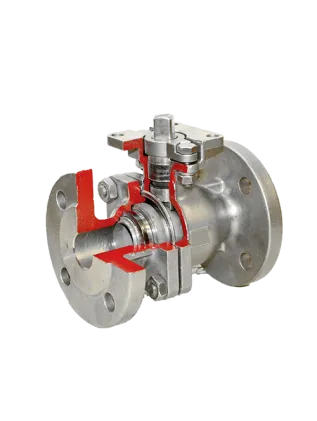

LXHQ-M2FY Two-piece full-bore high-platform hard-seal flanged ball valve

Product Overview:

The LXHQ-M2FY two-piece, full-bore, high-platform, hard-seal flanged ball valve features a metal-to-metal seal for superior resistance to high temperatures, wear, and corrosion. The valve body is a two-piece flange connection, which is compact and easy to disassemble and maintain. The top is equipped with an ISO 5211standard high platform, which can be directly installed with electric or pneumatic actuators. It is an ideal fluid cut-off device for high temperature, high pressure, particles, fibers and other harsh working conditions.

Product features:

Metal sealing structure, suitable for high temperature, high pressure, containing particles or viscous medium

Full diameter design, strong flow capacity, small pressure loss, not easy to block

High-platform interface, supporting direct installation of electric/pneumatic actuators without bracket

The valve seat and ball can be welded with hard alloy (such as STL, Ni60, WC, etc.) to improve wear resistance

Stable structure, small opening and closing torque, reliable sealing and long service life Two-way sealing function, the installation direction is not limited

Anti-blow-out valve stem structure to ensure safe operation of the system

Optional anti-static design and fireproof structure to meet the requirements of special working conditions

Technical parameters:

Nominal diameter: DN15 ~ DN200 (1/2 "~ 8")

Nominal pressure: PN16/PN25/PN40/ANSI 150LB ~ 300LB

Applicable temperature: -29 ° C ~ + 450 ° C (depending on surfacing material and structure)

Valve body material: carbon steel WCB, stainless steel CF8/CF8M, alloy steel, dual-phase steel, etc.

Ball material: stainless steel surfacing STL/Ni60/WC and other wear-resistant alloy

Valve seat material: metal surfacing + elastic pre-tightening structure/all-metal seal

Connection mode: flange (GB/ANSI/DIN and other standards)

Driving mode: handle, electric, pneumatic, hydraulic

Structure standard: API 608/GB/T 12237/ASME B1 6.34

Test standard: API 598/ISO 5208 Leakage Class: ANSI Class IV ~ V (Class VI can be customized)

Application industry:

High temperature steam delivery system

Process control of petrochemical, coal chemical and fine chemical industry

Catalytic cracking, coal gas, natural gas and other gas systems

Oxygen and gas cut-off in metallurgical steel industry

Boiler, feed water and superheater system of power plant

Coking, pulverized coal conveying and high pressure water washing system

Particle-containing and impurity-containing fluid or strong scouring condition