LXBG-PPH Propylene Glycol Phenyl Ether

LXBG-PPH Propylene Glycol Phenyl Ether

description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Information

Propylene Glycol Phenyl Ether LXBG-PPH

Chemical Description

Propylene Glycol Phenyl Ether(LXBG-PPH) is an organic compound that serves as a versatile solvent and additive invarious applications, particularly in the coatings and paints industry.

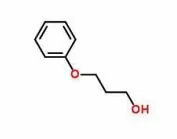

English Name: 1 - Phenoxy - 2 - Propanol

Structural Formula: C₆H₅OCH₂CH₂CH₂OH

Molecular Weight: 152.2

Product Feature

●Versatility: LXBG-PPH can be used in a wide variety of applications across different industries, making it a valuable ingredient in formulations.

●Improved Performance: It enhances properties such as adhesion, flow, leveling, and drying time, contributing to high-quality end products.

●Lower VOCs: When used in water-based formulations, LXBG-PPH can help reduce the overall volatile organic compound(VOC) emissions, making products more environmentally friendly.

●Compatibility: LXBG-PPH exhibits good compatibility with a wide range of other chemicals and additives, allowing formulators to create customized solutions.

Physical Properties

| Name | Appearance | Boiling point | Relative volatility | Solubility in water | Relative density | pH value | Color | Active ingredient |

|---|---|---|---|---|---|---|---|---|

| LXBG-PPh | Colorless transparent liquid | 242.7 | ≤0.01 | 1.1 | 1.045 - 1.065 | 7 ± 2 | <50 | ≥99 |

Application Recommendation

● Water-Based Architectural and Industrial Coatings

As a film-forming aid in latex paints to promote fusion of polymer particles and enhance coating performance.

● Textile Dyeing

Used as a carrier solvent to facilitate uniform dispersion and penetration of dyes into fibers, improving dyeing efficiency.

● Ink Industry

Suitable for ballpoint pens, felt-tip pen inks, stamp pad inks, and textile printing pastes to ensure ink fluidity and drying properties.

● Paint Strippers

Used in formulating paint removers to effectively dissolve old coatings for easy stripping.

● Latex Adhesives

Serves as a film-forming aid to enhance adhesive cohesion and bonding strength.

● Metal Working Fluids

Used to formulate uniform and stable metal working fluids, improving system rheology, reducing viscosity, and enhancing machining efficiency.

Performance Introduction

As an efficient film-forming additive for water-based latex and dispersions, it’s particularly effective in gloss and semigloss paints.

After optimization, LXBG-PPH (E) and (T) can be directly added at any paint-making stage, simplifying the process and improving stability in systems

LXBG-PPH is a colorless, transparent liquid with a pleasant sweet fragrance. Its nontoxic and eco-friendly nature significantly reduces VOC in coatings.

As an efficient film-forming additive for water-based latex and dispersions, it’s particularly effective in gloss and semigloss paints.

Acting as a strong solvent for polymers like vinyl acetate, acrylic, and styrene-acrylic, LXBG-PPH has low water solubility. This allows it to be fully

absorbed by latex particles, creating a continuous film. This enhances the latex paint’s coalescence and color development while ensuring good storage

stability. Compared to common film-forming additives like TEXANOL (or domestic alcohol ester-12), LXBG-PPH achieves the same film properties with

30-50% less usage. Its strong coalescing ability doubles film-forming efficiency, significantly reducing production costs. Added at 3.5-5% of the

emulsion, it can lower the minimum film-forming temperature (MFT) to -1℃.

After optimization, LXBG-PPH (E) and (T) can be directly added at any paint-making stage, simplifying the process and improving stability in systems

like pure acrylic emulsions. It’s recommended to add LXBG-PPH before the emulsion or during pigment grinding for better compatibility and stability.

Generally, for pure acrylic emulsions, the addition amount is 3.5-6%; for vinyl-acrylic emulsions, 2.5-4.5%; and for styrene-acrylic systems, 2-4%.

Suggested Addition Amount

● For pure acrylic emulsion: The addition amount is 3.5-6%.

● For vinegar-acrylic emulsion: The addition amount is 2.5-4.5%.

● For phenylpropylene: The addition amount is 2-4%

Packing and storage

Packing and storage

● 50kg plastic drums, 200kg plastic drums

● This product is non-dangerous goods and should be stored in a cool and dry place.