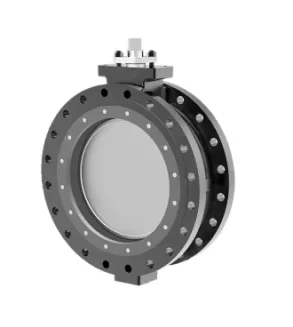

LXHQ-HT Three-bias high-performance butterfly valve

Product Overview:

LXHQ-HT triple eccentric high-performance butterfly valve adopts triple eccentric structure design to realize friction-free opening and closing between the valve plate and the valve seat, which completely overcomes the extrusion and abrasion between the sealing surfaces when the traditional butterfly valve is opened and closed, and significantly improves the service life and reliability of the sealing pair. The valve has zero leakage sealing capability, is widely applicable to high temperature, high pressure, high frequency opening and closing and working conditions with extremely high requirements on sealing performance, and meets the harsh application requirements of petrochemical, electric power, metallurgy, papermaking, shipping, natural gas and other industries.

Product features:

Three eccentric structure design: when opening, the valve plate is quickly separated from the sealing surface to realize friction-free opening and closing and prolong the sealing life

Hard to hard seal/hard to soft seal options for reliable sealing under high temperature and pressure

Zero leakage seal rating per ANSI Class VI

Small opening and closing torque, more stable operation, suitable for frequent opening and closing conditions

Adjustable valve seat design, easy field maintenance, improve the overall service life

High strength valve body structure, compression resistance, erosion resistance, high reliability

Applicable to a wide range of media: liquid, gas, steam, slurry, powder

Flexible driving mode: manual, electric, pneumatic and hydraulic options

Various installation forms: horizontal, vertical and any angle

Technical parameters:

Nominal diameter DN50 ~ DN2000

Nominal pressure PN10/PN16/PN25/PN40/PN63/ANSI 150LB ~ 600LB

Applicable temperature: -46 ° C ~ + 600 ° C (according to different sealing materials and structures)

Valve body material WCB/WC6/WC9/LCB/CF8/CF8M/duplex steel/alloy steel

Valve plate material: stainless steel, alloy steel, Hastelloy, Monel, etc.

Sealing material: 316 + STL, hard alloy, flexible graphite, PTFE, etc.

Connection type: flange type (EN 1092-1, ASME B16.5), wafer type, lug type

Leakage class per ANSI B16.104 Class VI (zero leakage)

Actuator manual, electric, pneumatic, hydraulic

Application industry:

Chemical

lietrochemical

Oil & gas

Steam

Food & Beverage

Machinery and equiliment

Air conditioning facilities

Toxic and lethal

General liiliing