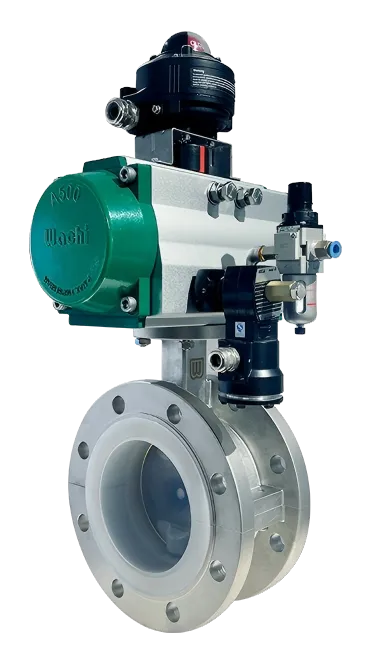

LXHQ-CLBVF lined flanged butterfly valve

Product Overview:

LXHQ-CLBVF lined flanged butterfly valve is a midline flanged butterfly valve with integral lining of anticorrosive materials (such as PTFE, PFA, FEP, PO, etc.) on the inner wall of the valve body and the surface of the butterfly plate. It has reasonable structural design, excellent corrosion resistance and sealing performance, and is especially suitable for strong corrosive media, clean working conditions and high-frequency opening and closing occasions. The opening and closing angle of the butterfly plate is 0 ° -90 °, which is flexible to operate. Standard flange interfaces are adopted on both sides of the valve body, which is convenient for installation and maintenance. It is widely used in chemical, pharmaceutical, food, environmental protection and water treatment industries.

Product features:

Full lining anti-corrosion design, suitable for strong acid, strong alkali, organic solvent and other corrosive media

Excellent sealing performance, bidirectional zero leakage, long service life

Compact structure, light weight and easy operation

Flange connection, easy installation and maintenance

Can be installed horizontally, vertically or at any angle

Low opening and closing torque, wide selection of driving device

Various lining materials to meet different medium working conditions

Support multiple driving modes: handle, electric, pneumatic and hydraulic

Technical parameters:

Nominal diameter DN50 ~ DN1200

Nominal pressure PN10/PN16/ANSI 150LB

Applicable temperature -20 ° C ~ + 180 ° C (depending on lining material)

Body Material Carbon Steel WCB/Ductile Iron/Stainless Steel CF8/CF8M

Lining material PTFE, FEP, PFA, PO, ETFE, PE, etc.

Butterfly plate material: stainless steel/nodular cast iron/fluorine-lined butterfly plate

Sealing material PTFE, FEP, PFA

Connection standard GB/T 9113/ASME B16.5/DIN EN1092-1

Leakage Class ANSI Class VI (zero leakage)

Drive mode: handle, electric, pneumatic, hydraulic

Application industry:

Petrochemical industry

Fine Chemical Industry

The pharmaceutical industry

Food and beverage industry

Textile and papermaking

Environmental protection equipment

Water treatment, sewage treatment

Semiconductor industry

Desulfurization and denitrification system

Paint and pigment industry